Stone Atta Chakki

10 Inch Small Atta Chakki Machine For Homes

Brand:

CONFIDER

★

★

★

★

★

Price ₹

14,000.00

| General Details: | |

| Modal | 10 inch small atta chakki machine for homes |

| Material | Mild Steel |

| Voltage | 220 V |

| Capacity | 15-25 kg/hr |

| Power Consumption | 1.125 KW |

| Usage/Application | Grain Grinding |

| Others: | |

| Motor rpm | 2800 |

| Operation Mode | Automatic |

| Purpose | Domestic, Home use, Home business, Startups |

| Stone thickness | 50 mm |

| Wheel Size | 10 inch |

| Condition | New |

| motor type | Copper winding |

| Power Rating | Single Phase |

| Model | SAC10_1 |

10 inch ghar ghanti atta chakki

Brand:

CONFIDER

Price ₹

18,200.00

| General Details: | |

| Modal | 10 inch ghar ghanti atta chakki |

| Material | Mild Steel |

| Voltage | 220 V |

| Capacity | 15-25 kg/hr |

| Power Consumption | 1.125 KW |

| Usage/Application | Grain Grinding |

| Others: | |

| Stone thickness | 50 mm |

| Wheel Size | 10 inch |

| Condition | New |

| Model | SAC10_2 |

| Motor rpm | 2800 |

| motor type | Copper winding |

| Operation Mode | Automatic |

| Power Rating | Single Phase |

| Purpose | Domestic, Home use, Home business, Startups |

1 HP Table Top Flourmill (Round Model)

Brand:

CONFIDER

Price ₹

11,500.00

| General Details: | |

| Modal | 1 HP Table Top Flourmill (Round Model) |

| Material | Mild Steel |

| Voltage | 220 V |

| Capacity | 5-6 kg/hr |

| Power Consumption | 0.75 KW |

| Usage/Application | Grain Grinding |

| Others: | |

| Machine Size | 24" X 13" X 10" |

| Condition | New |

| Model | TTF1R |

| Motor rpm | 2800 |

| motor type | Copper winding |

| Operation Mode | Automatic |

| Power Rating | Single Phase |

| Purpose | Domestic |

1 HP Table Top Flourmill (Square Model)

Brand:

CONFIDER

Price ₹

11,800.00

| General Details: | |

| Modal | 1 HP Table Top Flourmill (Square Model) |

| Material | Mild Steel |

| Voltage | 220 V |

| Capacity | 5-6 kg/hr |

| Power Consumption | 0.75 KW |

| Usage/Application | Grain Grinding |

| Others: | |

| Operation Mode | Automatic |

| Power Rating | Single Phase |

| Purpose | Domestic |

| Condition | New |

| Machine Size | 24" X 13" X 10" |

| Model | TTF1R |

| Motor rpm | 2800 |

| motor type | Copper winding |

1.25 HP Table Top atta chakki (Square Model)

Brand:

CONFIDER

Price ₹

12,600.00

| General Details: | |

| Modal | 1.25 HP Table Top atta chakki (Square Model) |

| Material | Mild Steel |

| Voltage | 220 V |

| Capacity | 7-8 kg/hr |

| Usage/Application | Grain Grinding |

| Others: | |

| Machine Size | 24" X 13" X 10" |

| Power Rating | Single Phase |

| Condition | New |

| Model | WF212 |

| Motor rpm | 2800 |

| motor type | Copper winding |

| Operation Mode | Automatic |

| Power Consumption | 1 KW |

| Purpose | Domestic |

1.25 HP Table Top atta chakki (Round Model)

Brand:

CONFIDER

Price ₹

12,200.00

| General Details: | |

| Modal | 1.25 HP Table Top atta chakki (Round Model) |

| Material | Mild Steel |

| Voltage | 220 V |

| Capacity | 7-8 kg/hr |

| Power Consumption | 1 KW |

| Usage/Application | Grain Grinding |

| Others: | |

| Operation Mode | Automatic |

| Power Rating | Single Phase |

| Purpose | Domestic |

| Condition | New |

| Machine Size | 24" X 13" X 10" |

| Model | TTF1P25R |

| Motor rpm | 2800 |

| motor type | Copper winding |

12 inch new attachakki flourmill

Brand:

CONFIDER

Price ₹

18,000.00

| General Details: | |

| Modal | 12 inch new attachakki flourmill |

| Material | Mild Steel |

| Voltage | 220 V |

| Capacity | 25-30 kg/hr |

| Usage/Application | Grain Grinding |

| Others: | |

| Motor rpm | 2800 |

| Chamber size | Stone thickness = 75 mm |

| Condition | New |

| Machine Size | Wheel Size = 12 inch |

| Model | SAC12 |

| motor type | Copper winding |

| Operation Mode | Automatic |

| Power Consumption | 1.5 KW |

| Power Rating | Single Phase |

| Purpose | Domestic, Home use, Home business, Startups |

12 inch home atta chakki

Brand:

CONFIDER

Price ₹

26,900.00

| General Details: | |

| Modal | 12 inch home atta chakki |

| Material | Mild Steel |

| Voltage | 220 V |

| Capacity | 25-30 kg/hr |

| Usage/Application | Grain Grinding |

| Others: | |

| Condition | New |

| Model | SAC12TP |

| Motor rpm | 2800 |

| motor type | Copper winding |

| Operation Mode | Automatic |

| Power Consumption | 1.5 KW |

| Power Rating | Single Phase |

| Purpose | Domestic, Home use, Home business, Startups |

| Stone thickness | 75 mm |

| Wheel Size | 12 inch |

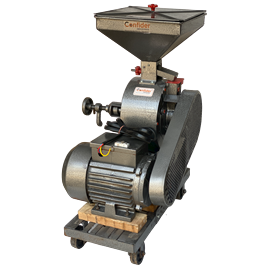

14 inch attachakki (Flourmill)

Brand:

CONFIDER

Price ₹

27,500.00

| General Details: | |

| Modal | 14 inch attachakki (Flourmill) |

| Material | Mild Steel |

| Voltage | 220 V |

| Capacity | 35-45 kg/hr |

| Usage/Application | Grain Grinding |

| Others: | |

| Condition | New |

| Operation Mode | Automatic |

| Purpose | Domestic, Home use, Home business, Startups, Business purpose, Commercial |

| Model | SAC14 |

| Motor rpm | 2800 |

| motor type | Copper winding |

| Power Consumption | 2.2 KW |

| Power Rating | Single Phase |

| Stone thickness | 75 mm |

| Wheel Size | 14 inch |

14 inch gharelu attachakki

Brand:

CONFIDER

Price ₹

29,200.00

| General Details: | |

| Modal | 14 inch gharelu attachakki |

| Material | Mild Steel |

| Voltage | 220 V |

| Capacity | 35-45 kg/hr |

| Usage/Application | Grain Grinding |

| Others: | |

| Condition | New |

| Model | SAC14TP |

| Motor rpm | 2800 |

| motor type | Copper winding |

| Operation Mode | Automatic |

| Power Consumption | 2.2 KW |

| Power Rating | Single Phase |

| Purpose | Domestic, Home use, Home business, Startups, Business purpose, Commercial |

| Stone thickness | 75 mm |

| Wheel Size | 14 inch |

16 Inch Atta Chakki

Brand:

CONFIDER

Price ₹

30,000.00

₹36,900.00

| General Details: | |

| Modal | SAC16 |

| Material | Steel |

| Voltage | 220 |

| Capacity | 60 - 7- kg/hr |

| Power Consumption | 3.75 KW |

| Electricity Connection | Three Phase |

| Usage/Application | Commercial, Business |

| Others: | |

| Stone Size | 16 Inch |

| Stones | Emery |

| Weight | 150 kg |

if you are interested, please fill the below details: